हमें कॉल करें Now

08045800720

| Comparison |

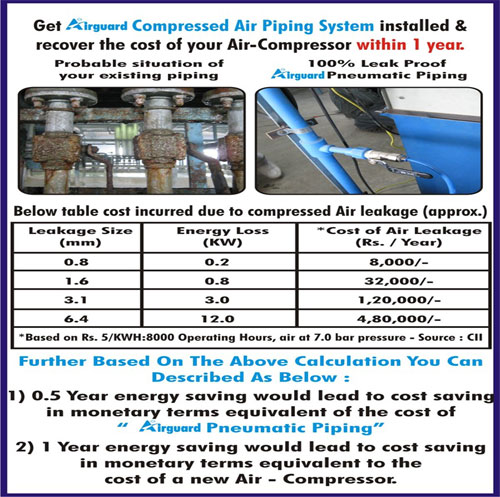

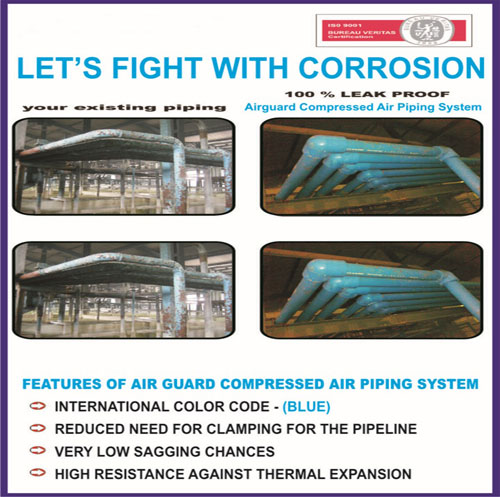

3.AIRGUARD PPR-FRP VS G.I PIPINGFOR AIR PIPING LINK AGAINST G.I PIPING

4.AIRGURD VS ALUMINIUMFOR AIR PIPING LINK AGAINST ALLUMINIUM PIPING

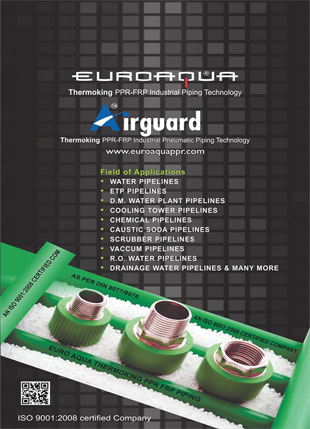

5.AIRGUARD VS SS PIPING EUROAQAU THERMOKING PPR FRP INDUSTRIAL PIPES WITH INTERNATIONAL COLOR CODE GRREN IS SPECIALLY DESIGNED FOR VARIAOUS INDUSTRIAL NEEDS LIKE HOT & CHILLED WATER ,CHEMICAL,ETP,HVAC MANY MORE….. | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| SR.NO | PROPERTIE |  | Thermal Fiber Reinforcement Sandwich Middle Layer (Raw Material) & OTHERS MAKE PPR |

| 1 | MOC(ROW MATERIAL) | We are using specialized imported raw material from lyondell basell- germany & hyosung corp- korea with body coat certificate | USE LOCAL RAW MATERIAL |

| 2 | BRAND | We have special brand for hot & cold water & Chemical Applications of SAKKHTI make under the Brand Name of EUROAQAU THERMOIKNG Polypropylene Random Co FRP PIPES & FITTINGS with International color code GREEN & International approved by 16 countries. | |

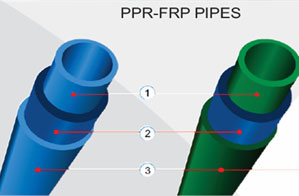

| 3 | SPECIALIZE MIDDLE LAYER |  the percentage of differnciate layer is 65% of middle layer,20% of upper Layer & 15% of bottom layer as per standard.100% LEAK PROOF JOINT |  high percentage of frp layer leads to poor joint that leads leakages after long period of time.Due to ppr-frp joint with Polypropylene Random Co fittings. |

| 4 | EFFECT OF UV RAYS | AS UPPER LAYER UV TRATED VERY NEGLIGIBLE OR NO EFFECT UNDER SUNLIGHT. | DUE TO TRANSPARANT UPPER LAYER UV RAYS PASSED & LIFE GET DECREASE WHEN EXPOSE TO SUNLIGHT |

8.WHY EUROAQAU FOR CHEMICAL & ETP APPLICATIONS

EUROAQUA PPR -FRP TECHONOLGY IS SPECIALLY DEVELOP FOR VARIOUS CHEMICAL & ETP APPLICATIONSPolypropylene Random Co PIPE HAS EXCELLENT CHEMICAL & TEMPRATURE RESISTANCE.

IT CAN BE USED FOR PASSING ALMOST ALL ACIDS & ALKALINE CHEMICAL MEDIA.

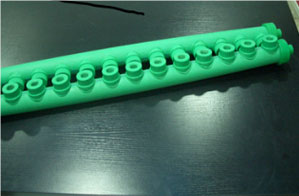

AS INNER SURFACE IS ANTIMICROBIAL & MIRROR LIKE SMOOTHER SURFACE NO LIME STONE OR NO POLAR NATURE,NO BACTERIAL & fungal growth.

9.EURO AQAU Polypropylene Random Co VS HDPE

FOR Polypropylene Random Co PIPING LINK AGAINST HDPE PIPING

| SR.NO | PROPERTIE |  | HDPE |

| 1 | SERICE LIFE | 50 YEARS | 10-15 YEARS |

| 2 | TEMPRATURE RESISTANCE | UPTO-5*C TO 95*C | UPTO ONLY 60*C |

| 3 | HEAT LOSS | NEGLIGIBLE | MODERATE |

| 4 | RESISTANCE TO EXPOSE TO SUNLIGHT(uv) | VERY GOOD(DUE OUTER LAYER UV STABLIZED,UV TREATED) | POOR TO SUNLIGHT(START TO DECOMPOSE).IT IS NOT UV TREATED. |

| 5 | JOINING METHOD |  SOCKET FUSION WELDED(100% HOMOGENOUS CONNECTUIONS) |  BUTT WELDED(SURFACE TO SURFACE JOINT) BUTT WELDED(SURFACE TO SURFACE JOINT) |

| 6 | SAGGING ISSUE | VERY NEGLIGIBLE DUE TO INBUILT INSULATED FRP COMPOUNDED MATERIAL | VERY HIGH SAGGING ISSUES DUE TO NO SPELIAZE LAYER PRESENT. |

10.EURO AQAU Polypropylene Random Co VS UPVC,CPVC

FOR Polypropylene Random Co PIPING VIDEO LINK AGAINST PVC,CPVC& UPVC

| SR.NO | PROPERTIE |  | PVC, UPVC & CPVC |

| 1 | SERVICE LIFE | 50 YEARS | 20-30 YEARS |

| 2 | TEMPRATURE RESISTANCE | UPTO-5*C TO 95*C | UPTO ONLY 60*C |

| 3 | HEAT LOSS | NEGLIGIBLE | MODERATE |

| 4 | FOOD GRADE | EXCELLENT-HYGEINIC | NON-HYGEINIC |

| 5 | RESISTANCE TO EXPOSE TO SUNLIGHT(uv) | VERY GOOD(DUE OUTER LAYER UV STABLIZED,TREATED) | POOR TO SUNLIGHT(START TO DECOMPOSE).IT IS NOT UV TREATED. |

| 6 | CHEMICAL EXCELLENT | VERY GOOD | GOOD |

| 7 | JOINING METHOD | SOCKET FUSION WELDED(100% HOMOGENOUS CONNECTUIONS) | SPECIAL SOLVENT CHEMICAL |

| 8 | JOINING RELIABLITY | 100% LEAK PROOF | NOT 100% LEAK -PROFF DUE TO CHEMICAL JOINING |

| 9 | FRICTION FACTOR | VERY LOW | LOW |

| 10 | CHEMICAL RESISTANCE | EXCELLENT-HYGEINIC | GOOD |

?

?